As pioneers in the Metal Manufacturing Industry, we aspire to set new trends, leaving an indelible mark, while maintaining a zero-tolerance policy towards any adverse impact on the environment and ensuring flawless products with zero defects.

Who We are

Fidel Metal, based in Jamnagar, India, shines as a premier Manufacturer, Exporter, and OEM Supplier of Ferrous and Non Ferrous Metal Components. Our reach extends across the globe, serving esteemed clients in India and offshore regions. Renowned for our technologically advanced components with exceptional performance, we have earned global recognition.

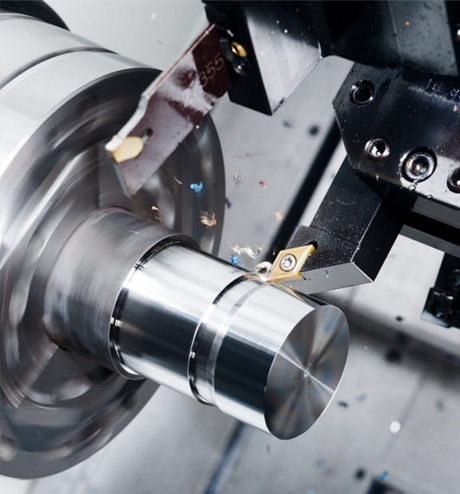

Equipped with state-of-the-art machinery, skilled team, comprehensive measuring instruments, and seasoned management, we ensure superior quality at the best prices. Our ISO 9001 certification underscores our commitment to excellence. Continuously embracing advanced technologies and fostering a culture of learning through our Customer Policy, we stay at the forefront of the industry, while prioritizing health and environmental policies.

Catering to diverse industrial assemblies and applications, we are the go-to source for medium to high-volume production of Brass Electrical Parts, Brass Spacer & Stand Off, Brass Fasteners, Brass Fittings, Metal Stamping Parts etc., we meet specific drawing tolerances with finesse

Brass

Brass is made from zinc and copper, and it’s known for its gold appearance and effectiveness during machinability. Brass is used to make products such as:

- Electrical devices

- Bushings

- Handles

- Lamp parts

- Marine parts

- Electrical devices

- Valves

- Architectural hardware fittings

- Door & Glass Fittings

- Bearings

Some of the properties that make brass an excellent material for use in machining include:

- Low melting point

- Easy casting abilities

- Nonmagnetic properties

- Corrosion and tarnish resistance

- Excellent malleability

- No need for surface finishing

- Low friction

Stainless Steel

Stainless steel is ideal for many applications because it has much greater resistance to rust and corrosion than other varieties of steel. Stainless steel consists of an alloy comprising primarily iron and chromium; chromium present in stainless steel can bond with floating oxygen particles, forming solid chromium oxide on the steel’s surface. This means that stainless steel has a limited ability to "heal" itself from scratches and abrasions.

Stainless steel is used to build a wide variety of objects, including:

- Industrial equipment

- Medical devices

- Aerospace and automotive components

- Military hardware

- Architectural fittings

Stainless steel owes a lot of its valuable traits to passivation, a chemical process during which acids remove excess iron from the material’s surface, resulting in an inert oxide layer that protects the steel from rusting.

Mission Statement

Vission Statement

Driven by our visionary aspirations, we strive to ascend as the unrivaled market leader in brass industries. Our unwavering focus revolves around producing exceptional quality products, relentlessly delivered at competitive prices.

Corporate Value

We are dedicated to enhancing performance at every turn. With meticulous execution of flawless planning, we ensure a consistent delivery of superior quality products, always on time. We focus on customer centric approach.

Office

Jamnagar - 361 004. Gujarat - INDIA.